Beiben axles are a core component of Beiben Heavy Truck, employing Mercedes-Benz's most advanced production technology and adhering to Mercedes-Benz technical standards. They achieve international leading levels in material selection, manufacturing processes, and performance optimization. The axle housing is made of high-strength ductile iron, combined with an integral internal expansion casting process to ensure no deformation under heavy loads. The main reducer's spiral bevel gear pair uses an equal-height tooth design, increasing strength by approximately 20% compared to similar domestic products. The product range covers a full series of drive axles and steering axles, featuring wide transmission ratios, high load-bearing capacity, and high reliability, and is widely used in Beiben tractors, dump trucks, and off-road vehicles operating in complex road conditions.

Beiben Heavy Truck, relying on its profound military industrial heritage and Mercedes-Benz technology, has created a series of robust, durable, high-load-bearing, and high-transmission-efficiency axle products. Our axles are the core assembly for vehicle power transmission, load bearing, and control, making them the first choice for harsh working conditions and efficient transportation due to their superior reliability.

I MAIN AXLES TYPE OF BEIBEN TRUCKS

Beiben Axles is a professional manufacturer of heavy-duty axles that has introduced German Mercedes-Benz technology and achieved independent innovation. Its products cover a full range of commercial vehicles and special vehicles and are known for their reliability and technical adaptability.

• Main categories:Front axles(Drive axle, non-drive axle); Middle axles(Drive axle); rear axles(Drive axle)

• Common Axle Loads:Front axles(Drive axle):6.5T / 7T / 7.5T;Front axles(Non drive axle)7T / /7.5T / 13T;Middle /rear axles(Drive axle):13T / 16T / 18T

• Main models: HL7/015DS-13 drive axle; HL7/015DS-13 drive axle; HL6_33D-13; HD6_27DG-13; HD7/016DGS-13 Universal Drive Axle; AL7-10DGS-8 Drive Axle

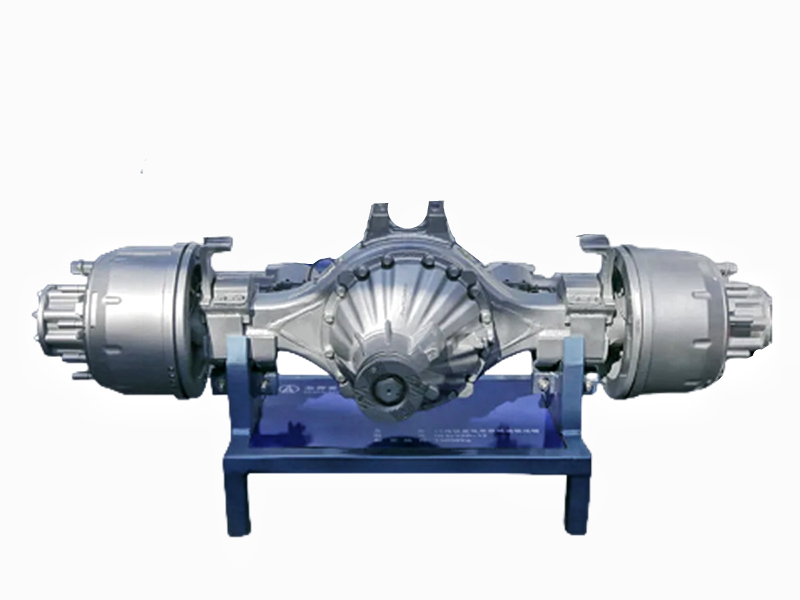

I MAIN COMPONENTS OF BEIBEN TRUCKS AXLES

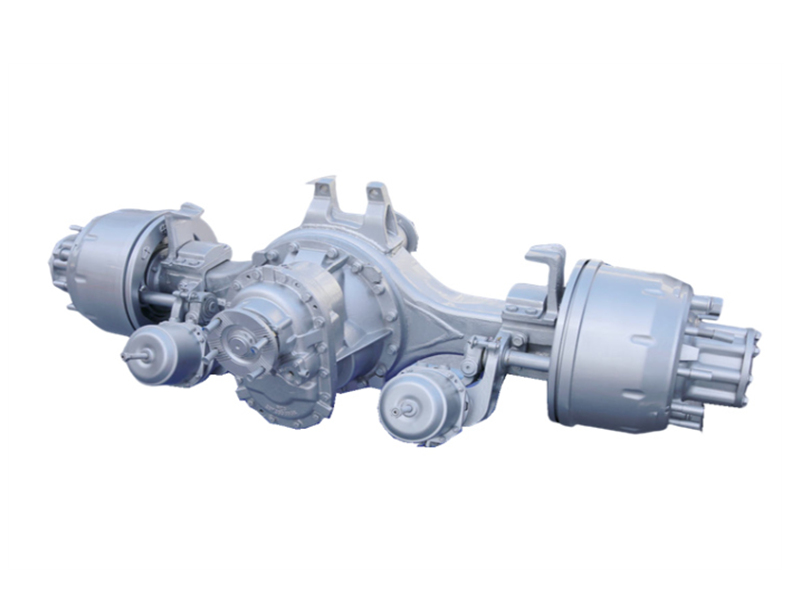

★ Front Axle (Steering Axle)

• The front axle, located at the front of the vehicle, is a crucial component connecting the chassis and front wheels, primarily bearing steering function and some vertical loads.

• Some Beiben models use front-wheel drive for power transmission.

• It mainly consists of the front axle beam, steering knuckle, kingpin and steering linkage, wheel assembly, and brakes.

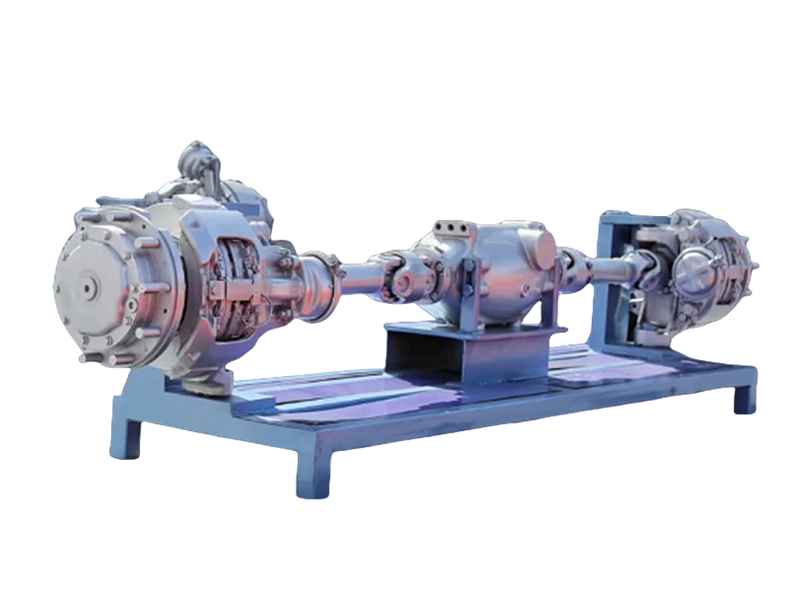

★ Middle Axle (Drive Axle)

• In 6x4 and 8x4 drive configurations, the middle axle is one of the core drive axles, forming a powerful dual-drive system together with the rear axle.

• It mainly consists of the through-shaft assembly, final drive and differential, half-shafts, axle housing and suspension interface, braking and wheel system, etc.

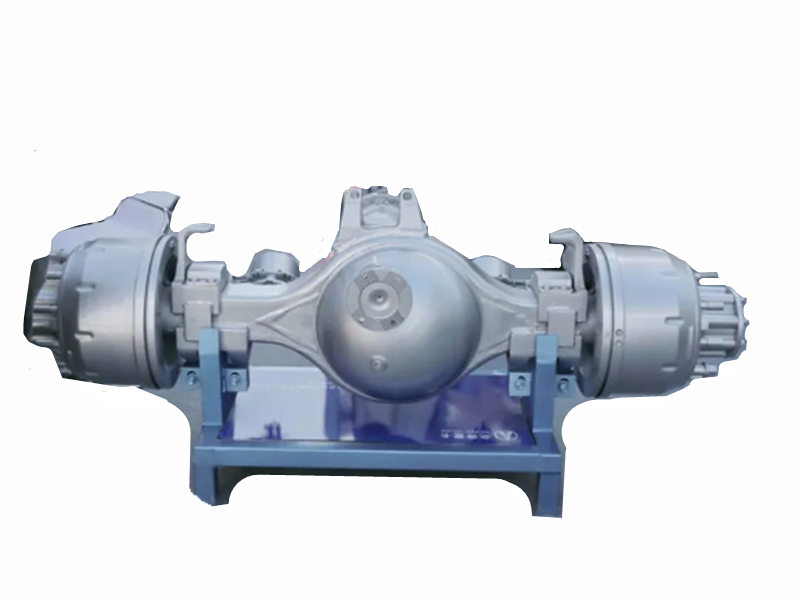

★ Rear Axle (Drive Axle)

• The rear axle is the terminal for vehicle power output, directly driving the wheels and bearing all vertical loads. The Beiben rear axle assembly includes the axle housing assembly, final drive, half-shafts, differential housing assembly, inter-wheel differential lock, wheel-side reduction gear assembly, wheel assembly, cast brakes, and drive axle piping logic assembly, among other components.

I MAIN BEIBEN TRUCK AXLES

Beiben 742.A02 Drive Axle

– Heavy-duty logistics and engineering mainstay vehicles: Rated axle load 30 tons, curb weight 1240kg, gear ratio 9.716, maximum output torque 75,000N-m, the most powerful drive axle in the Beiben conventional series.

– Braking configuration: Employs Φ500×200mm large-size S-cam drum brakes, enhancing braking safety on long downhill slopes, suitable for 8×4 heavy-duty dump trucks and large engineering vehicles.

Beiben AL7-10DGS-8 Drive Axle

– Economical Multi-Purpose Axle: Rated axle load of 8 tons, curb weight of 750 kg, gear ratio of 4.769/53263, maximum output torque of 20,000 N·m, key features include low maintenance costs and durability.

– Applicable Vehicles: Medium-sized engineering vehicles, rural trucks, brake size Φ410×160 mm, balancing braking efficiency and lightweight requirements.

Beiben 733.A Split Drive Axle

– Multi-scenario adaptability: Adopts classic split axle housing (pipa-style) design. Rated axle load 8 tons, maximum output torque 20000 N·m, gear ratio 5.921/5.263/4.769; 20” air disc brakes.

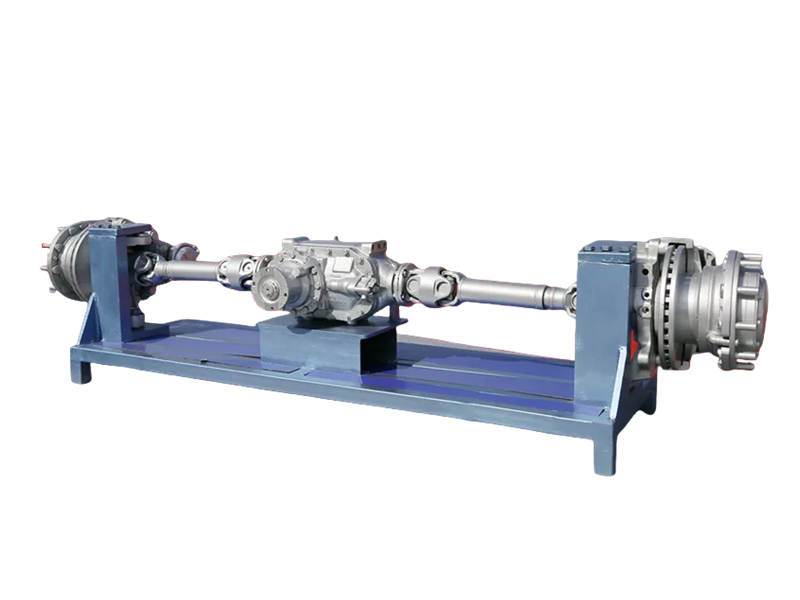

Beiben Through-Type HD6_27DG-13 Drive Axle

– Core hub of the dual-drive system: As the core axle model for 6x4 vehicles, it has a rated axle load of 13 tons. It weighs 1507kg, has a maximum output torque of 40000 N·m, and transmission ratios of 5.286/4.111/3.7/3.364/3.083/2.846. It features Φ410×180 cam drum brakes and is suitable for general cargo transportation, as well as short- and medium-distance engineering transportation scenarios.

Beiben HD7/016DGS-13 Universal Drive Axle

– Versatile Adaptability: Rated axle load of 13 tons, curb weight of 740kg, gear ratio of 3.083, maximum output torque of 55,000 N·m, suitable for general cargo transportation as well as short- and medium-distance engineering transportation.

– Reliable Design: Standard Φ410X180X18 mm brakes, proven in salt spray and high-humidity environments (e.g., Southeast Asian and African markets).

Beiben Single-Speed Reduction HL6_33D-13 Drive Axle

– Precise Load Bearing, Stable Drive: As the primary drive axle in a tandem drive axle configuration, it has a rated axle load of 13 tons, a curb weight of 1507 kg, 22.5” air disc brakes, and gear ratios of 5.286/4.111/3.7/3.364/3.083/2.846, with a maximum output torque of 40000 N·m. Designed specifically for conventional heavy-duty transportation, it provides a reliable power transmission foundation.

Beiben HL7/015DS-13 Drive Axle

– Lightweight and efficient transportation: Rated axle load of 13 tons, tare weight of only 740kg, maximum output torque of 55,000 N-m, gear ratio of 4.769, Φ410X180X18"S" cam drum brake, optimized for logistics tractors to reduce no-load fuel consumption.

- Technical highlights: Gear ratio of 4.769, balancing power and fuel economy, suitable for high-speed long-haul transportation.

I BEIBEN HEAVY TRUCKA CORE AXLES SYSTEM COMPARISON

|

Characteristic |

Front Axle (Steering Driven Axle) |

Front Drive Axle (Steering Drive Axle) |

Middle Axle (Drive Axle) |

Rear Axle (Drive Axle) |

|

Main functions: |

1. Bear the front load 2. Achieve steering 3. Withstand braking and impact |

1. Bears the front load and outputs power 2. Enables steering 3. Provides additional driving force and traction |

1. Bears the central load and outputs power 2. Power distribution core (for twin-axle axles) |

1. Bears the rear load and outputs power 2. Provides maximum traction and off-road capability |

|

Core structural components |

- Front axle beam - Steering knuckle - Wheel hub assembly - Brakes |

- Drive axle housing with final drive reducer - Universal joint type drive steering knuckle - Constant velocity half shaft - Wheel hub assembly and inter-wheel differential |

- Drive axle housing - Main reducer and differentia - Fully floating half shaft - Through shaft output end |

- Drive axle housing - Main reducer and differential - Fully floating half-shafts - Inter-wheel differential lock (core) |

|

Key technical features |

- Simple and reliable structure - Low steering resistance - Optional disc brakes |

- Highly complex integration of drive and steering systems - High ground clearance design - Standard inter-wheel differential, with optional differential lock - High steering angle requirements |

- High transmission efficiency and load-bearing capacity - Inter-axle differential carrier - Optional wheel-side reduction |

- Superior load-bearing capacity - Differential lock configuration as the core - Forms a rigid dual-drive system with the middle axle |

|

Typical rated axle load |

6.5T / 7T / 7.5T |

7T / /7.5T / 13T |

13T / 16T / 18T |

13T / 16T / 18T |

|

Core speed ratio |

not applicable |

Must be exactly the same as the speed ratio of the middle/rear drive axle:4.76; 5.263; 5.921; 6.733 |

Wide range: (4.769; 5.263; 5.921; 6.733; 7.63) |

The speed ratio must be exactly the same as that of the middle axle.(4.769; 5.263; 5.921; 6.733; 7.63) |

|

Differential and Lock |

none |

Standard configuration: Inter-wheel differential Advanced option: Inter-wheel differential lock |

Standard configuration: Inter-axle differential Optional configuration: Inter-axle differential lock |

Standard configuration: Inter-wheel differential Core option: Inter-wheel differential lock |

|

Applicable vehicle models/drive types |

4x2, 6x4, 8x4 and other conventional models |

Special front axles for all-wheel drive vehicles such as 4x4, 6x6, and 8x8. |

The first drive axle of 6x4, 8x4 and other vehicle models |

4x2 main drive axle 6x4/8x4 secondary drive axle |

|

Typical application scenarios |

Road freight transport, general engineering transport |

Extremely harsh road conditions: mining areas, oil fields, forests, high-altitude mountains, and military applications. |

Heavy-duty road transport, general engineering dump truck |

All scenarios that require strong driving force |

I HOT SALE BEIBEN TRUCK AXLES PARTS

| Driven Front Axle Parts Catalog | Non-Drive Front Axle Parts Catalog |

| Intermediate Axle Parts Catalog | Rear Axle Parts Catalog |

I APPLICABLE MODELS OF BEIBEN TRUCK AXLES PARTS